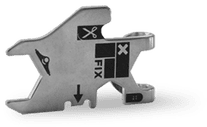

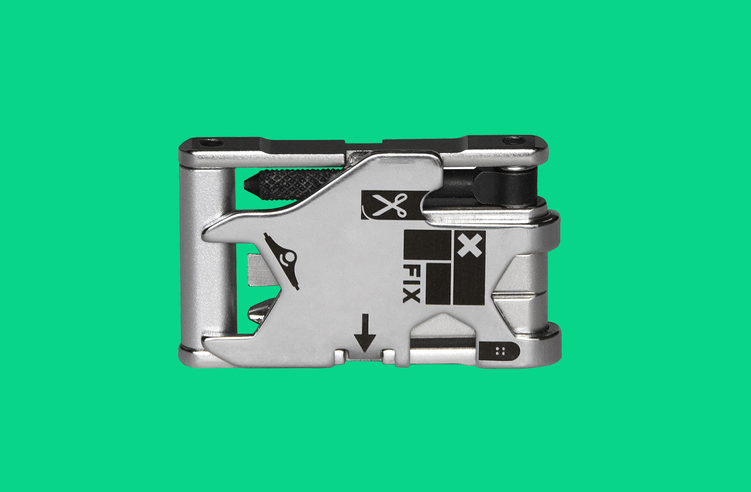

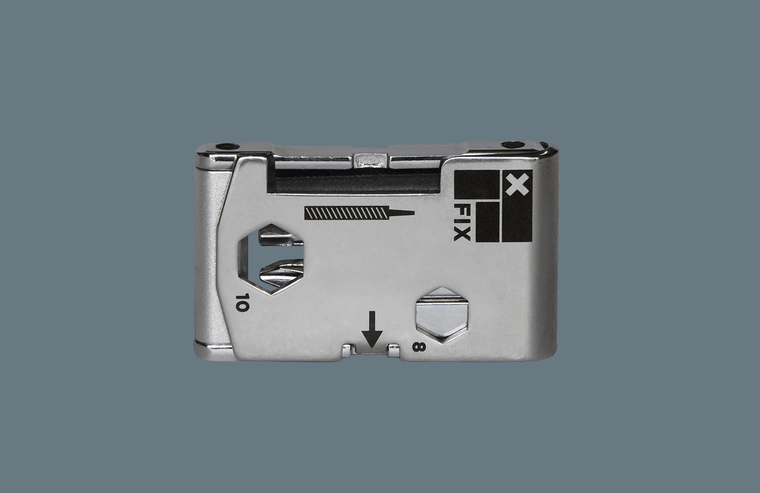

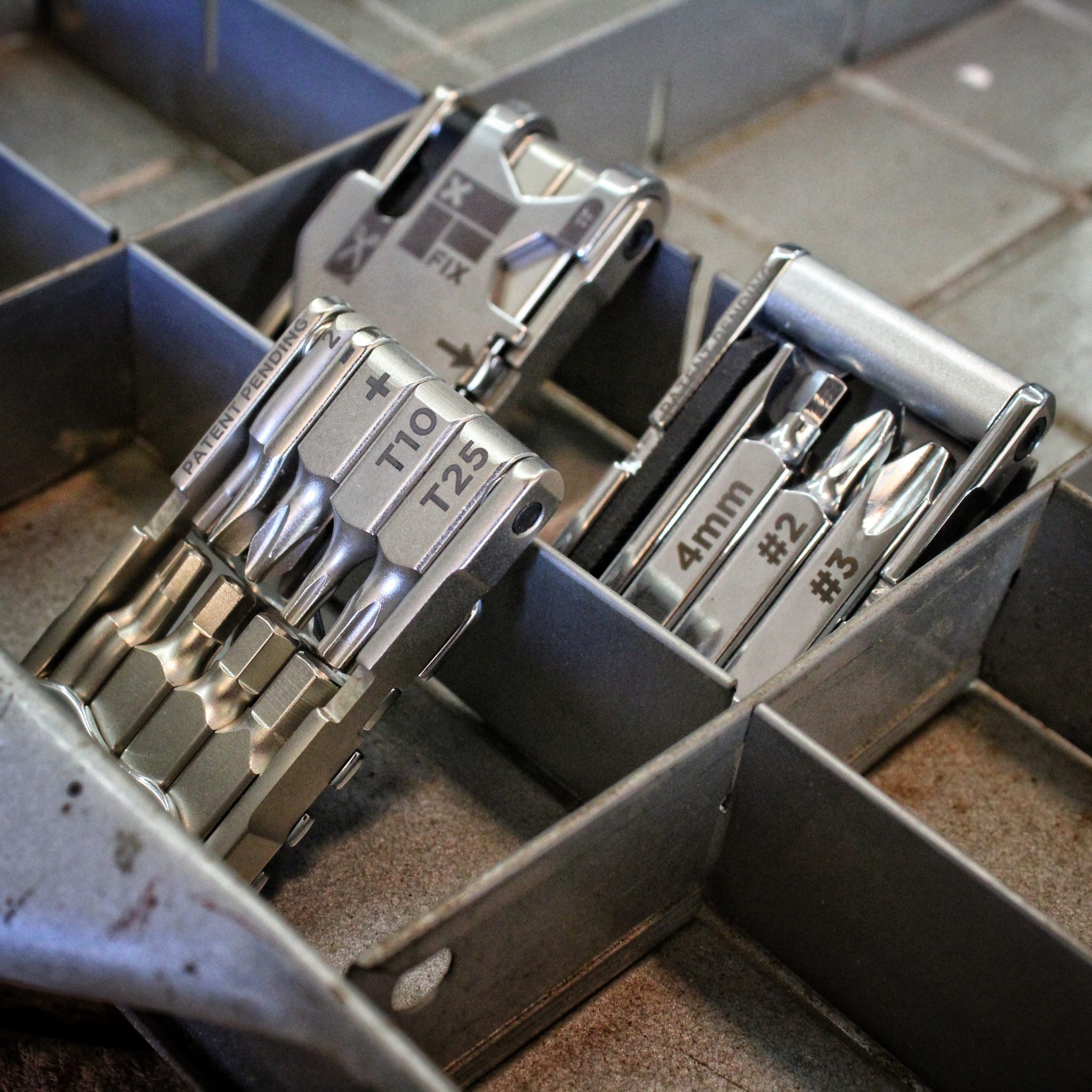

Quality metal tools.

There’s lot’s of options for metals when it comes to tools.

Two of the biggest factors to consider are tool life and corrosion. Let’s look at both in a little more detail.

When it comes to tool life, a high carbon alloy steel will have the hardness and abrasion resistance desired to apply the proper force on most fasteners. Aluminum would be nice and light, but does not have the hardness needed.

Since our tools will be used around sweat, snow, dirt, and more – corrosion is a big concern. Many people wonder why stainless steel is not used more for multi-tools in these environments. Stainless steel has some nice anti-corrosion properties but most alloys have reduced tool hardness. Stainless is also extremely expensive. For the “J-wrench” portion of our Board Sword and Powder Pliers, we do use stainless steel only because that part of the tool sees less torque. For most of our tools we add vanadium to our carbon steel alloy and finish with a nickel plating.

All of our tools undergo a salt water corrosion test for 24-48 hours. If anything is going to destroy a tool, it will be salt water.

Be glad that we stand behind our tools, and if you are ever less than satisfied don’t hesitate to contact us at tools@fixmfg.com